DEAR STAKEHOLDERS,

EOG’s mission, to be among the highest return, lowest cost, and lowest emissions producers, supports the dual challenge of the energy transition – to supply reliable, affordable energy while addressing climate change risk. Even with the changing global energy landscape, EOG has delivered consistent financial and operational results while focusing on leading environmental performance and maintaining safe operations. EOG’s consistency can be tied directly to our strategy—an enduring commitment to capital discipline, operational excellence, and sustainability, all underpinned by EOG’s unique culture.

EOG’s commitment to safe operations and environmental performance draws on the same decentralized structure, operational and technological focus, and innovative culture that drive our leadership in the exploration and development of our oil and natural gas plays. This commitment is supported by our workforce and the disciplined investments we make in our assets, infrastructure, and new technologies.

Joined OGMP 2.0

In early 2023, EOG joined the Oil and Gas Methane Partnership 2.0 (OGMP 2.0), a comprehensive, measurement-based reporting framework for the oil and gas industry designed to improve the accuracy and transparency of methane emissions reporting.

Established Conservation Lease with New Mexico State Land Office (NMSLO)

In 2023, EOG began work to establish an innovative conservation lease with the NMSLO. The conservation lease, spanning nearly 600 acres of land previously leased by EOG, was developed to promote the continued conservation of biodiversity, land, and archaeological resources in a multiuse area after completion of required reclamation and remediation activities. The partnership leverages EOG’s expertise in responsible land management and our ability to collect and utilize data to measure performance.

Broad Recognition from Energage's Top Workplaces

EOG continues to be recognized as a Top Workplace through the Energage survey, a designation awarded to companies that create a positive work environment by prioritizing a people-centered culture and giving employees a voice.

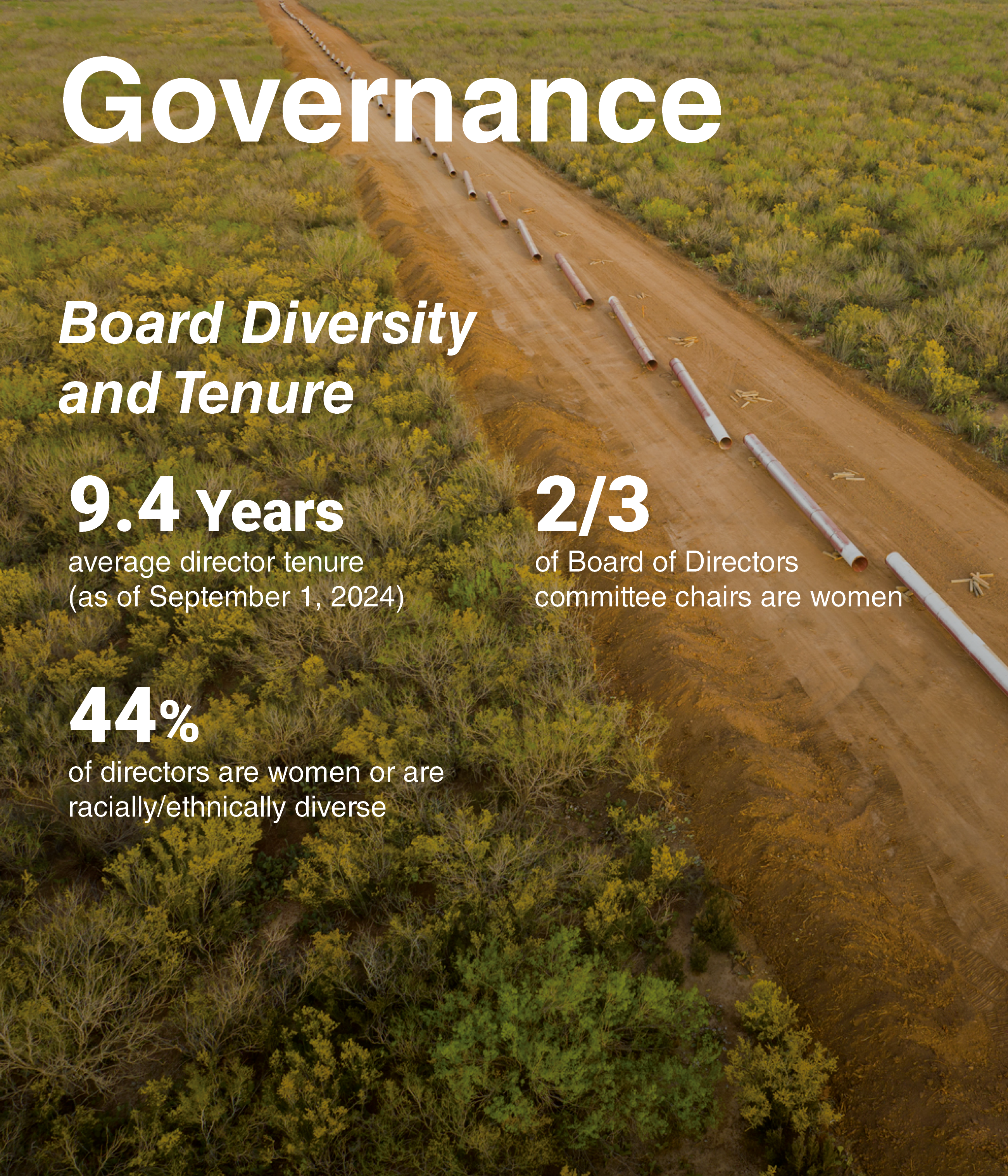

Strong Corporate Governance Practices

EOG’s strong corporate governance practices enhance Board of Directors and management accountability to our shareholders as well as our commitment to transparency to our other stakeholders and enhance our risk oversight and management efforts.

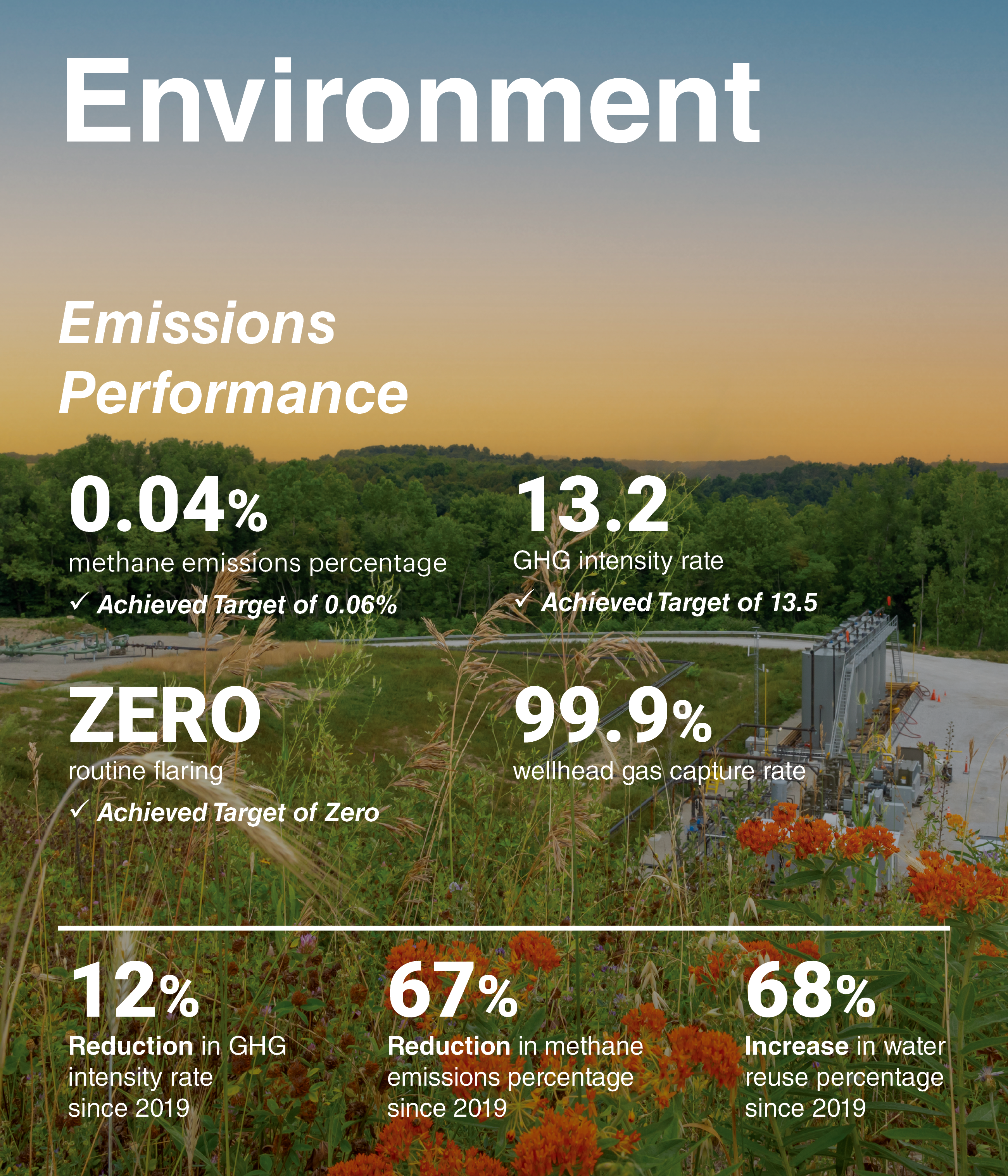

2023 Safety and Environmental Annual Performance Goal

In 2023, the Compensation and Human Resources Committee again established a separately weighted safety and environmental annual performance goal and increased the weighting to 15%, with the safety portion of the goal weighted 7.5% and the environmental performance metrics collectively weighted 7.5%. The goal included the following:

- Safety performance metric: total recordable incident rate

- Environmental performance metrics: oil spill and recovery rates, GHG, methane, and flaring emissions intensity rates, and wellhead gas capture rate